-40%

Small Elevating /Lifting Furnace Max. Temperature 1200 ℃ Φ120×120mm w/ Crucible

$ 2629.43

- Description

- Size Guide

Description

Small Size Elevating /Lifting FurnaceI

Product introduction

Small Size Elevating /Lifting Furnace,

which mainly provides high temperature heat treatment environment for the laboratories of institutions of higher learning,scientific research institutions,factory enterprises. And it applies to inorganic materials, nano materials heat sintering and also can be used for tooth sintering in the dental industry .

II

Product Features:

1. High purity alumina ceramic fiber as chamber material with no powder drops off in high temperature and with the advantage of

small heating capacity and saving energy more than 50%.

2. Quality heating elements are placed around the chamber with excellent temperature uniformity .

3. Fasting heating speed , 0-20℃/min and can be set freely .

4.

The imported temperature control instrument with high precision of temperature control and has the temperature compensation and correction function at precision ±1℃

5.PID temperature control instrument with program function .Heating curve can be set with program for 16 groups and 30 segments per group.

6. Instrument heating curve can be recorded at real time and the data can be saved automatically for printing experimental data connecting with computer.

7. Integrative structure design with precise lifting platform at the bottom for lifting smoothly and also well sealed .

8.

With alerting signal for the over-temperature during the working process,which can complete protective action automatically.

9.

When programs are set and press the starting button, the following steps will proceed automatically.

10.

Optional installation of gas inlet pipe is available and it can inlet inert gas for purging and protecting .

Model

Volume

Chamber size (mm)

Max. temp.

Working

temp

Voltage

Power

Heating element

Temperature

precision

STS-120-12

2L

Φ120×120

1200

℃

1150

℃

220V

2KW

HRE

±

1

℃

STS-150-12

3L

Φ150×150

1200

℃

1150

℃

220V

3KW

HRE

±

1

℃

STS-200-12

6L

Φ200×200

1200

℃

1150

℃

220V

4KW

HRE

±

1

℃

STS-300-12

20L

Φ300×300

1200

℃

1150

℃

380V

6KW

HRE

±

1

℃

STS-120-14

2L

Φ120×120

1400

℃

1350

℃

220V

3KW

SIC

±

1

℃

STS-150-14

3L

Φ150×150

1400

℃

1350

℃

220V

4KW

SIC

±

1

℃

STS-200-14

6L

Φ200×200

1400

℃

1350

℃

220V

5KW

SIC

±

1

℃

STS-300-14

20L

Φ300×300

1400

℃

1350

℃

380V

6KW

SIC

±

1

℃

STS-120-17

2L

Φ120×120

1700

℃

1650

℃

220V

3KW

MoSi

2

±

1

℃

STS-150-17

3L

Φ150×150

1700

℃

1650

℃

220V

4KW

MoSi

2

±

1

℃

STS-200-17

6L

Φ200×200

1700

℃

1650

℃

220V

4KW

MoSi

2

±

1

℃

STS-300-17

20L

Φ300×300

1700

℃

1650

℃

380V

8KW

MoSi

2

±

1

℃

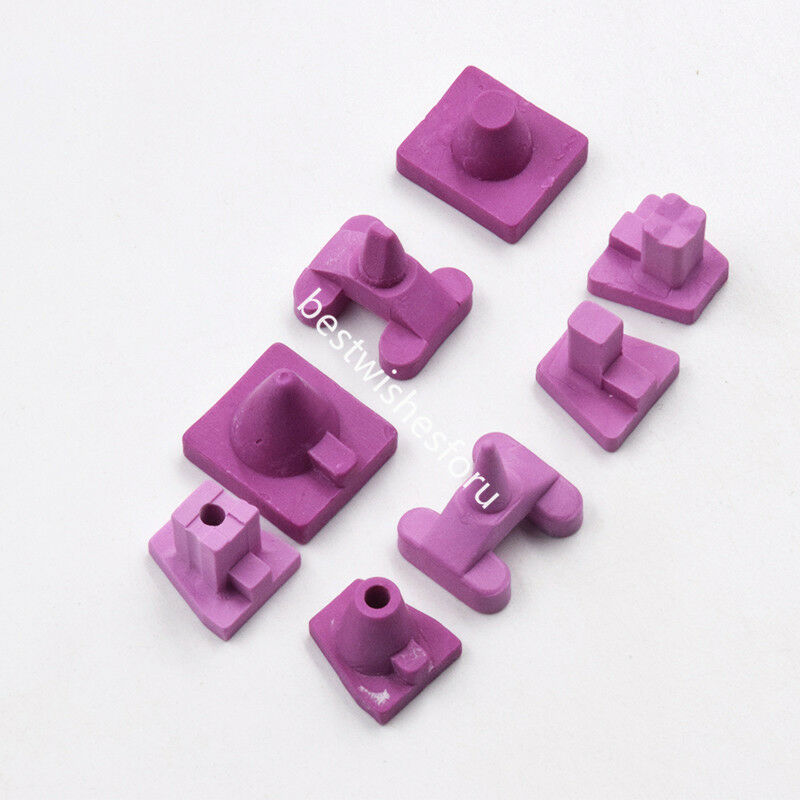

Standard accessories

Crucible tong

High temperature gloves

Optional accessories

Alumina crucible

Alumina Sintering Pallet