-40%

Dekema Sintering Furnace AUSTROMAT µSiC for Zirconia

$ 4224

- Description

- Size Guide

Description

Dekema Sintering Furnace AUSTROMAT µSiCThe sintering flagship, especially designed for sintering huge amounts of milled dental restorations. Three SiC heating elements ensure an even temperature distribution inside the sintering chamber. Process safety and trace-ability is already integrated through quality management modules and internet connectivity for remote access.

Furnace for sintering zirconia up to 1.600 °C

Large milling centers all over the world cherish the efficiency of the AUSTROMAT µSiC; efficiency in throughput, efficiency in energy consumption, efficiency through reliability.

Several levels of diameters up to 100mm can be placed on top the multilayered insulation table, up to a height of 150mm; this, sintering of more than 120 units is possible at a time. Discoloration can be neglected through the use of clean SiC heating technology. Energy saving heating and cooling processes extremely reduce sintering times. Depending on the material, typically around 70% shorter cycles can be realized as with conventional heating techniques in standard high temperature ovens. This is future-oriented, eco-sensitive stat-of-the-art technology for the process safety of tomorrow`s digital dental laboratory.

Editing and programming functions allow generation of incredible sintering cycles. The network compatible AUSTROMAT µSiC can remotely be operated. Use your mobile device or let us diagnose the unit remotely. Use a QR reader to optionally one button program or safely start a cycle. Even during program run you remotely may adapt data. Comprehensive backup and recovery functions an power failure features round up this furnace.

Features of Dekema Sintering Furnace AUSTROMAT µSiC:

Size (H x W x D):

990 x 416 x 602mm3

Weight

78kg

Power Supply

100-240 V / 50 to 60 Hz

Maximum Power Consumption

2 kW

Tmax

1600 °C

Touch Screen

✘

USB-terminal

✔

Programming languages

classic

DEKEMA vacuump pump

✘

DEKEMA AUTODRY

✔

Program resumption after power failure

✔

Presss functionality

✘

PTA(Press Time Automatic)

✘

MPTA(Multiple Press Time Automatic)

✘

Housing: Anodized aluminum

✔

Corporate Desing Customization

✘

Quartz glass heating element: DEKEMA specific heating element coil guided in pure quartz glass

✘

SiC heating element: DEKEMA specific, high purity heating elements made of SiC(silicon carbide), firing at high temperatures, no discoloration

✔

Fiber insulation 6xx: DEKEMA Specific fiber insulation

✘

Stone insulation 6xx: DEKEMA internally fabricated, specific stone insulation

✘

Multi-compound fiber insulation: Multilayer insulation for sintering at high temperatures

✔

Fiber insulation table: For firing porcelain, adapted to the dimensions of the furnace

✘

Stone insulation table: DEKEMA internally fabricated, for firing porcelain

✘

Stone insulation table: DEKEMA internally fabricated, for pressing porcelain

✘

Multi compound fiber insulation table: For sintering at high temperatures

✔

trixpress: Ring former for pressing several units/shades; 100g, 200g and 380g

✘

Sintering accessories: sintering in one level

✘

Sintering accessories: sintering in second level

✘

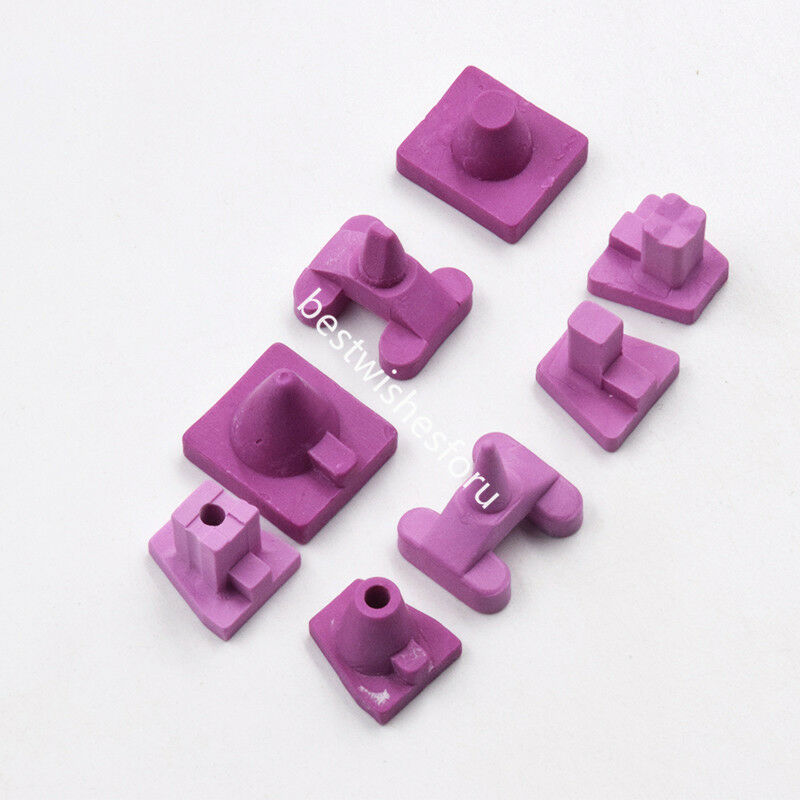

Package of µSiC sintering accessories: Three (3) bases and three (3) rings including gripper for reliably loading and unloading

✔

Micro-Pearls:non-deforming sintering of dental restorations

optional

Sintering plate for Micro-Pearls

optional

QR Reader

optional

USB interface: Transfer firing programs(dds)/transfer image files(jpeg)/save quality management files(dfl)

2x(✔,✔,✔)